Machining

Machining Services

Our machining services include:

- Milling

- Turning

- EDM (Precision: 0.01mm)

- Wire Cutting (Precision: 0.002mm)

- Flat Grinding

- Curve Grinding (Precision: 0.001mm)

- Optical Grinding (Precision: 0.001 mm)

Secondary Machining Services:

- Tapping

- Engraving

- Surface Treatments

- Surface Finishing

- Anodizing

- Hard Coating

Our Service Guarantee

√ Unrivaled accuracy and precision

√ On time delivery

√ Machining services for any budget

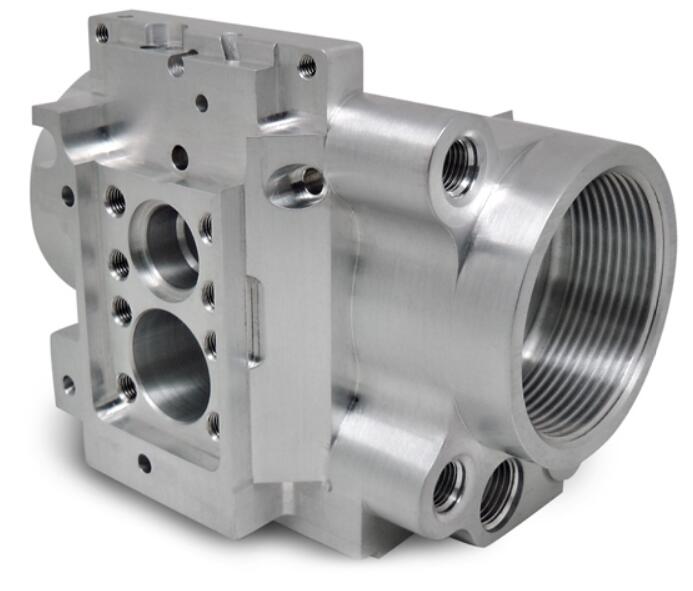

Our capabilities span 3-axis, 4-axis, and 5-axis CNC machines, encompassing vertical milling machines, horizontal milling machines, and lathes.

Milling & Turning

EDM & Wire Cutting

Flat Grinding & Curve Grinding

Optical Grinding

Secondary Machining Services Further refining your parts, we offer a suite of secondary machining services:

Tapping & Engraving

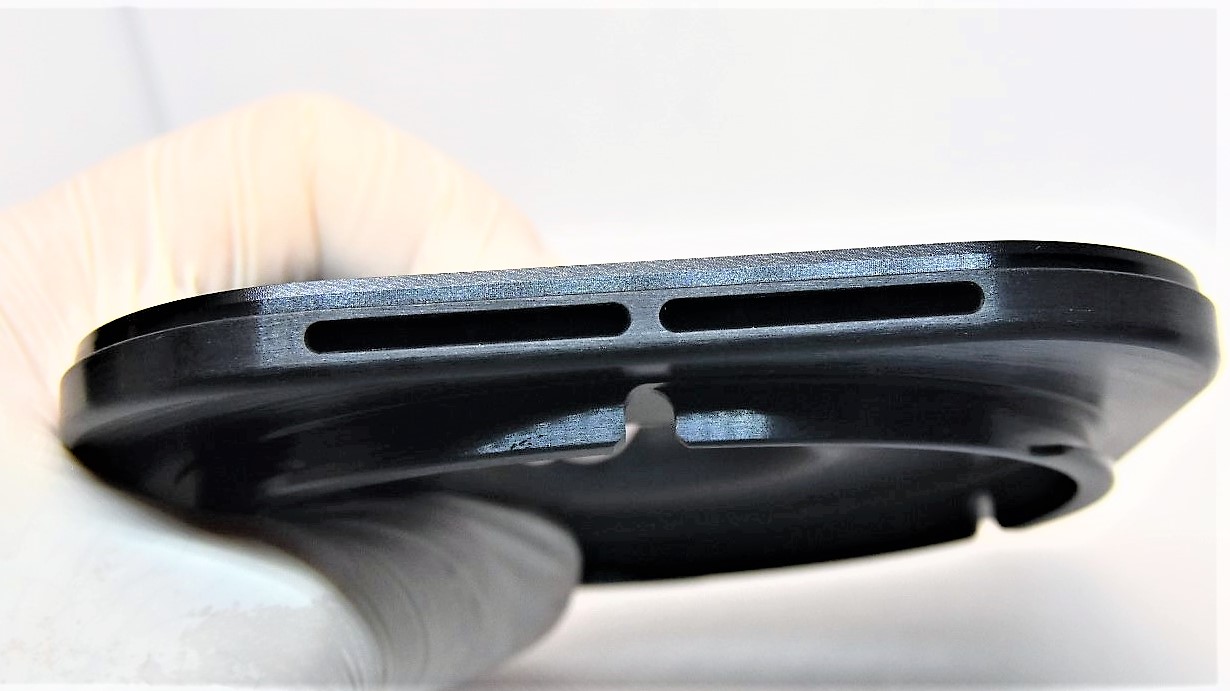

Surface Treatments & Finishing

Anodizing & Hard Coating

Partner with us and let our CNC machining services elevate your production efficiency and output quality. We’re here to turn your manufacturing demands into high-precision realities.

Why Choose Voyager Engineering’s CNC Machining Services

Our commitment to precision, quality, and efficiency sets us apart:

- Expertise: Our team of skilled technicians harnesses decades of experience to deliver top-tier machining services.

- Advanced Technology: We utilize state-of-the-art 3-axis, 4-axis, and 5-axis CNC machines, EDM machines, Grinding machines, allowing us to tackle complex designs with precision.

- Broad Industry Applications: From aerospace to the medical sector, our services cater to a diverse range of industries.

- Intellectual Property Protection: We prioritize your intellectual property protection, following strict processes within a secure facility.

- Material Selection: Choose from a wide variety of metal and plastic materials to meet your specific needs.

- Exacting Precision: Our CNC machining services deliver a tolerance accuracy up to 0.001 many shops can’t achieve

- Fast Turnaround: We offer expedited lead times for on-demand reorders, ensuring your projects stay on schedule.

Choose Voyager Engineering for a CNC machining experience that prioritizes your unique needs and project requirements.

Our equipment includes:

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Equip. name

Projecto

Microscope

Mirometer

Altimeter

Caliper

2D Test Instrument

Plugging force experimental machine

Surface roughness tester

X-Ray

Environment Test Chamber

Thermal Shock Tester

Steam aging test

Salt spraying test

Baking Test

Rockwell hardness tester

Vickers hardness tester

3D Measurement

Tool Microscope

Type of machine

CPJ-A3000

XTJ-4400

TA138(B)

U30B-F

505-681

-

-

-

XULM-XYm

MBU-80L

/

MC-833E

MC-952C

MC720

-

-

CNC654

MM-800

Brand

MITUTOYO/EASSON

Oka/MT

KTJ

SONY

MITUTOYO

MICRODOT

MingChi

Kosakaliab

Fischer

MingChi

MingChi

MingChi

MingChi

MingChi

MITUTOYO

MITUTOYO

Serein

Nikon

Qty /set

47

106

40

72

121

3

6

2

2

2

1

2

2

5

1

2

1

1

What Can We Help You With Today?

Get a fast, competitive quote on your machining project.