Manufacturing Excellence | Uncompromising Quality | Scalable Solutions

Precision Plastic Injection Molding Services

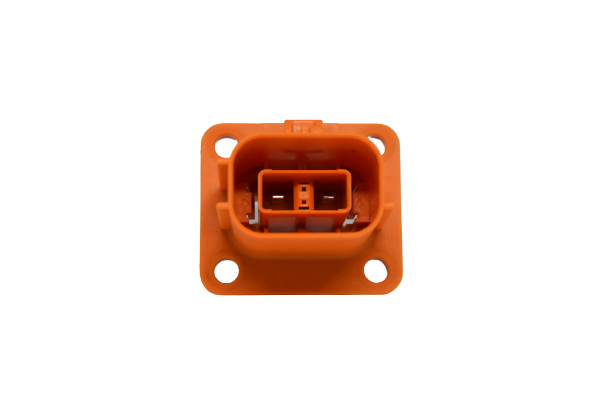

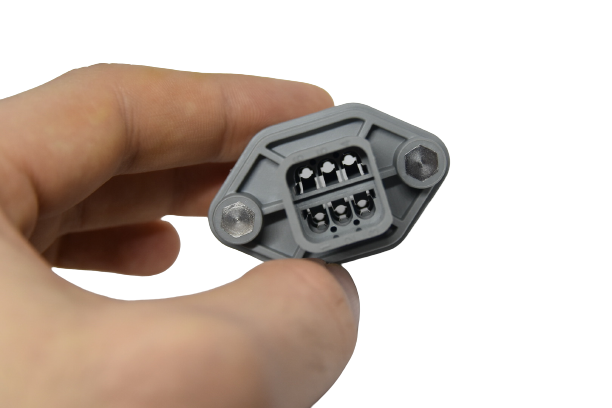

High-Quality Molding Solutions for Complex Parts

Voyager Engineering delivers precision injection molding solutions for complex components. Our advanced capabilities ensure consistent quality, optimal performance, and cost efficiency for mission-critical applications

Our Injection Molding Capabilities

Advanced Injection

Molding Capabilities

Thermoset Injection Molding

Precision Molding Equipment

Our facility features electric and hydraulic injection molding machines with clamping forces from 15 to 135 tons, ensuring precision and repeatability.

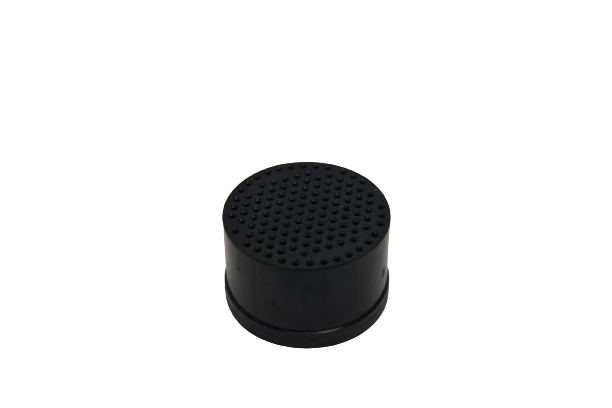

High Surface Finish: Up to SPI A1 for superior aesthetics.

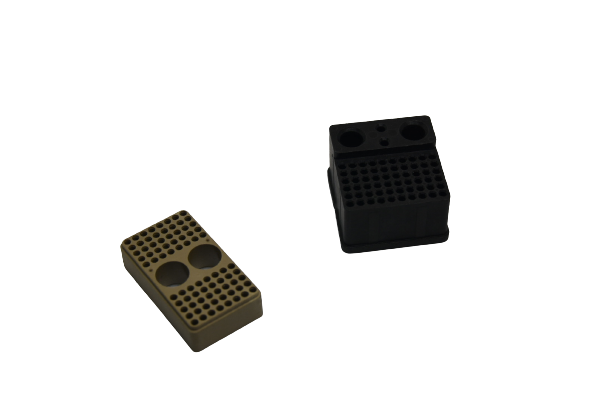

Advanced Molding Techniques: Dual shot molding, co-molding, micro molding, overmolding, and insert molding.

Automation Integration: Fully automated systems for consistent quality and cost efficiency.

Materials We Mold

Thermoplastics: ABS, Polycarbonate, Nylon, PEEK, and more.

Thermosets: Epoxy, Phenolic, and high-performance polymers.

Serving Mission-Critical Industries

Certified Quality

and Consistency

How It Works

Submit Your RFQ

DFM Review

Quote Approval

Precision Manufacturing

QC & Delivery

Why Choose Us for Injection Molding?

Our commitment to precision, quality, and efficiency sets us apart:

Get a Competitive Quote for your Injection Molding Parts Today

Get a fast, competitive quote on your Injection Molding project.